· Issac Hutley · Projects · 4 min read

Resistor Sorter

Computer-Controlled Through-Hole Resistor Logistics Machine

The Messy Drawers Problem

At Bradley University, there are a few electrical engineering labs that have large storage drawers containing different passive components used for experiments, one of which is through-hole resistors.

Because they are a core electrical component, we generally have lots of resistors on hand in many drawers. This can be hard to manage logistically when many students, some of whom have never seen these components before, need to remove and replace resistors correctly. The incorrect storage of these resistors has led to many headaches and frustrated trips back to storage to fetch a few resistors in the hope that one is of the correct value.

The Resistor Sorter machine is designed to sort resistors of different values into the correct storage drawers, thus solving the problem of manually trusting puny humans to return resistors to the correct bin.

Project Design

The project is planned to take multiple semesters to complete due to complexity, but we accomplished our goal of getting the machine to move to different drawers, given the value of an incoming resistor, within two semesters.

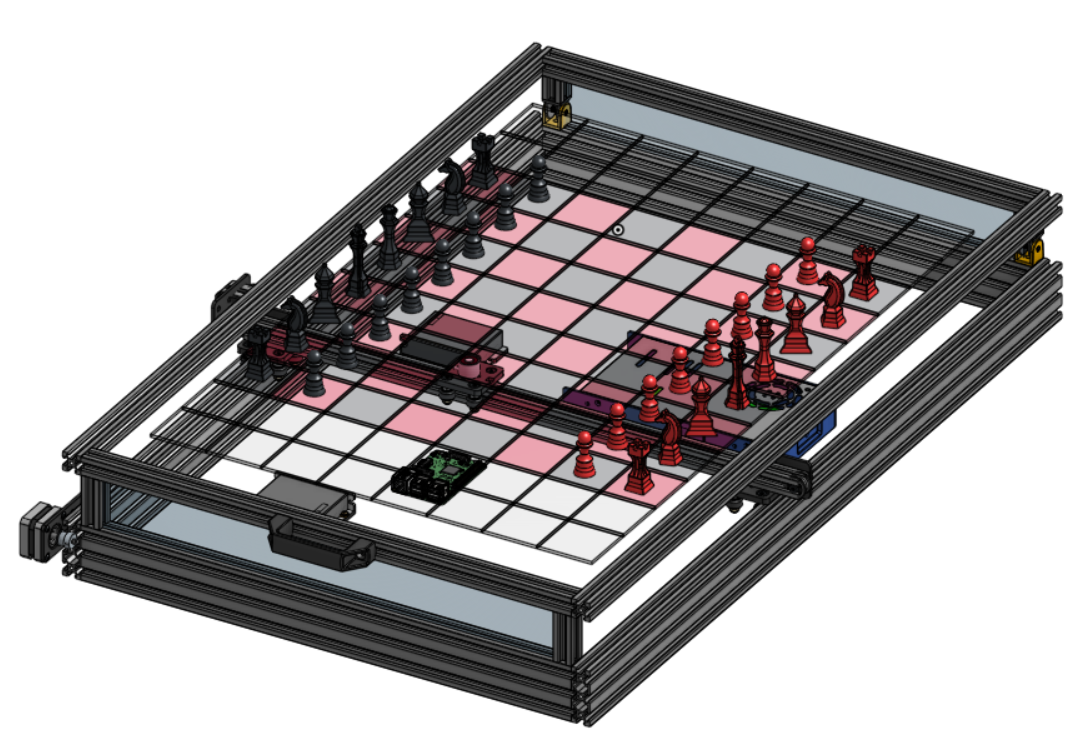

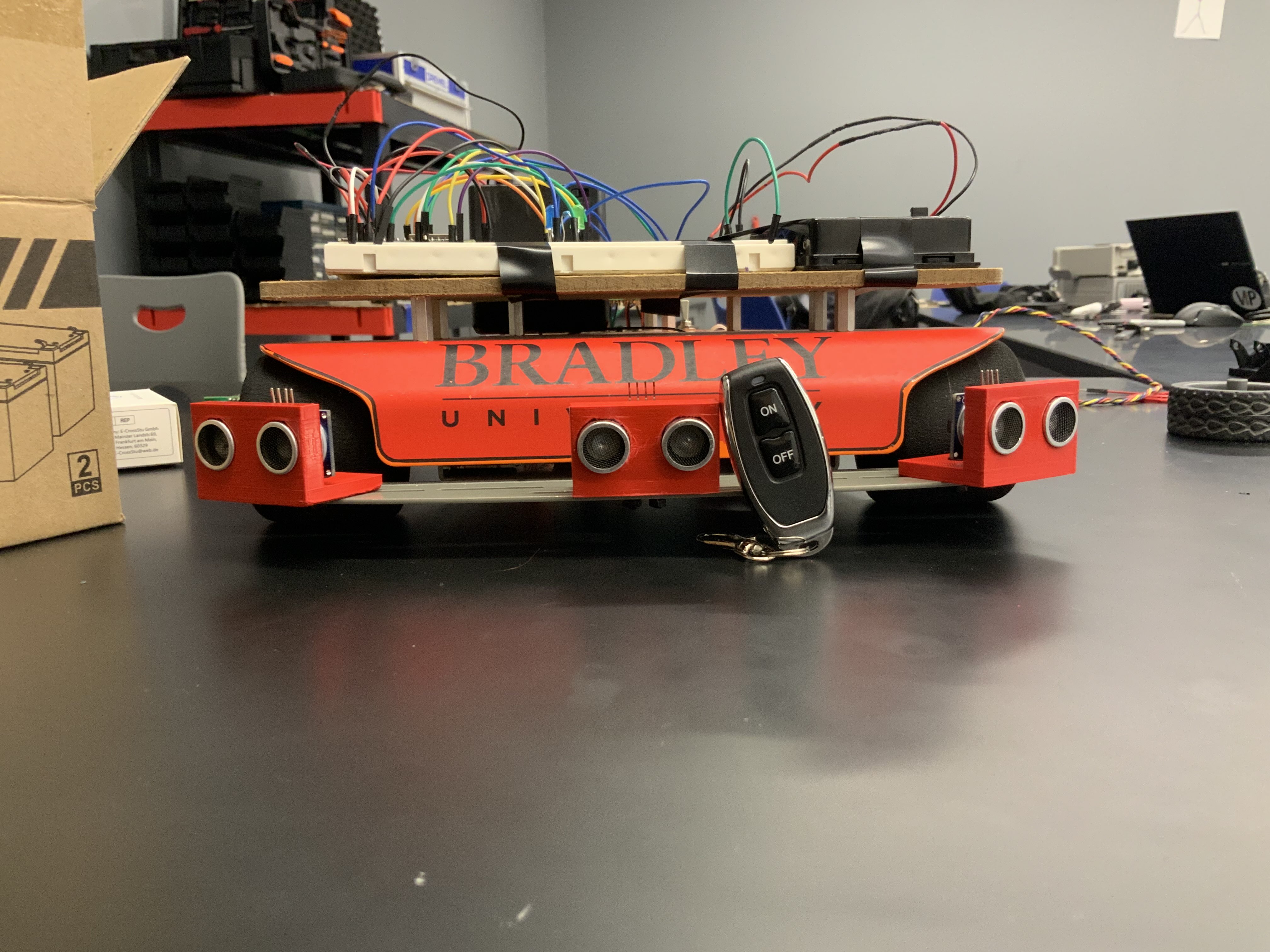

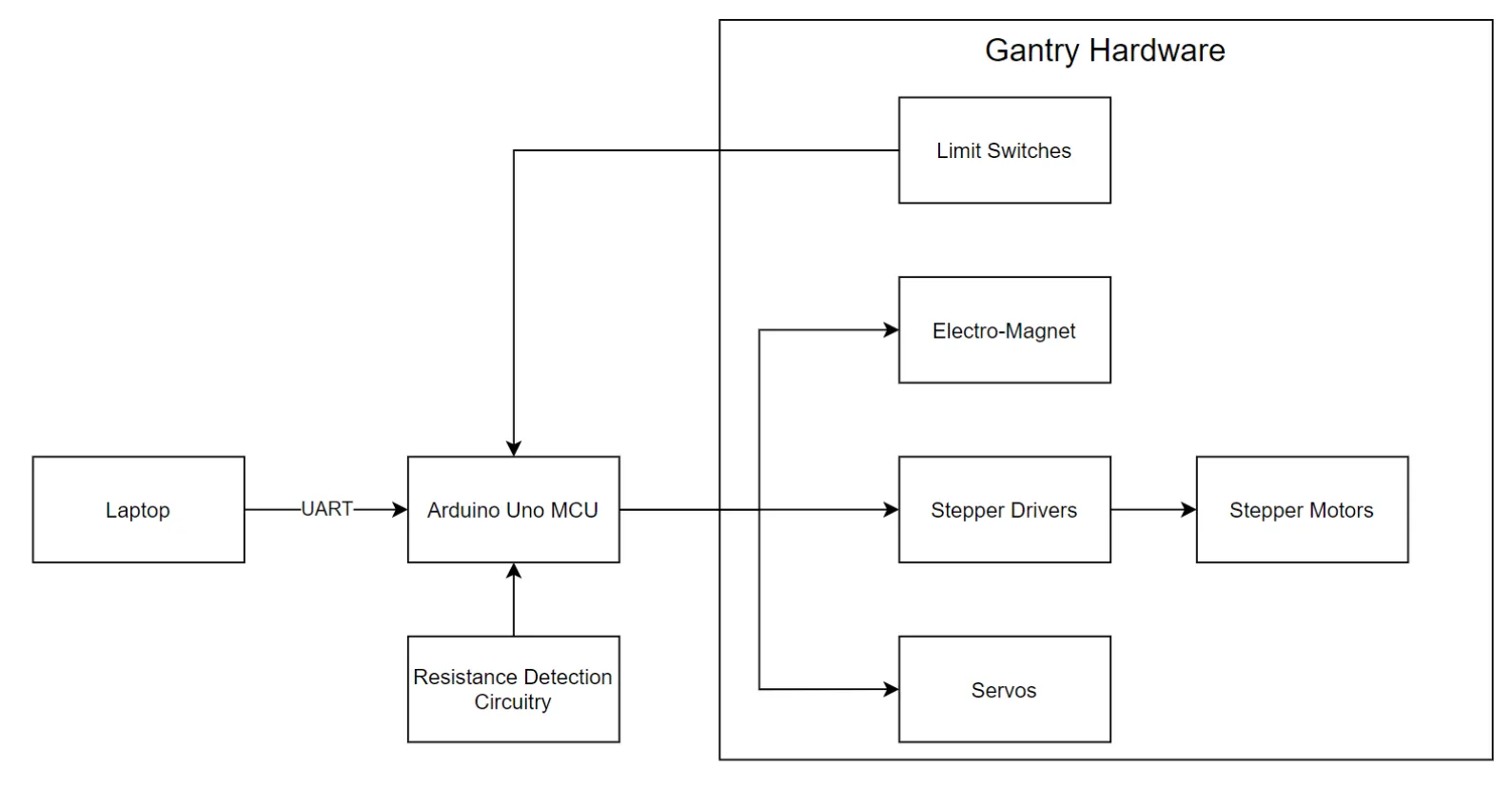

The Resistor Sorter is made from a number of different components. The most important of which are the stepper motors and the Arduino. The first stepper motor moves the gantry left and right, and the second moves the entire platform that the gantry is on up and down. The Arduino uses code and a pair of stepper motor drivers to drive the motors on the gantry and move the end-effector.

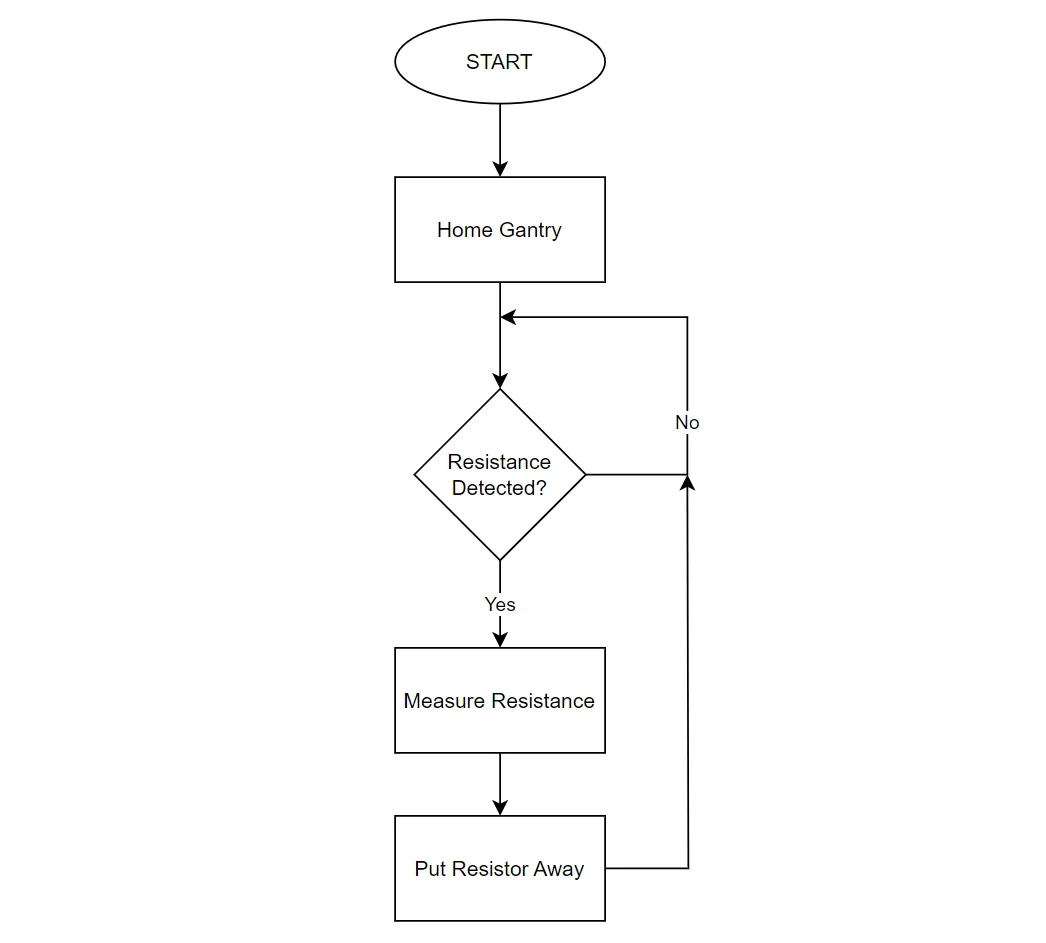

The code lets the gantry move to its starting position from startup, no matter where it is, and from there move to any position that is input (within the bounds of the cabinets). It can return to its starting position using a homing program and a limit switch, inspired by many 3D printers. It can then take any resistor value that’s input and move to the corresponding cabinet.

Hardware

The resistor sorter machine needed to be strong, but still easy to change as the design evolved. For these requirements, our team decided to use 20mm profile aluminum extrusion for building the frame. All of the motors and supporting hardware are attached to this extrusion.

As for the motors, the resistor sorter uses some NEMA 17 bipolar stepper motors to move the gantry and effector around. These motors drive a variety of shafts and belts directly for the X and Y axes.

The end-effector uses a rack-and-pinion system to move the electromagnet closer to the drawer to open it. The pinion is driven by a servo hidden inside the end-effector.

Electrical

The resistor sorter project uses stepper motors to control the gantry, similar to most 3d printers, and a couple of servos to control the end effector. The end-effector is responsible for opening and closing drawers with an electromagnet and dropping resistors into the drawers.

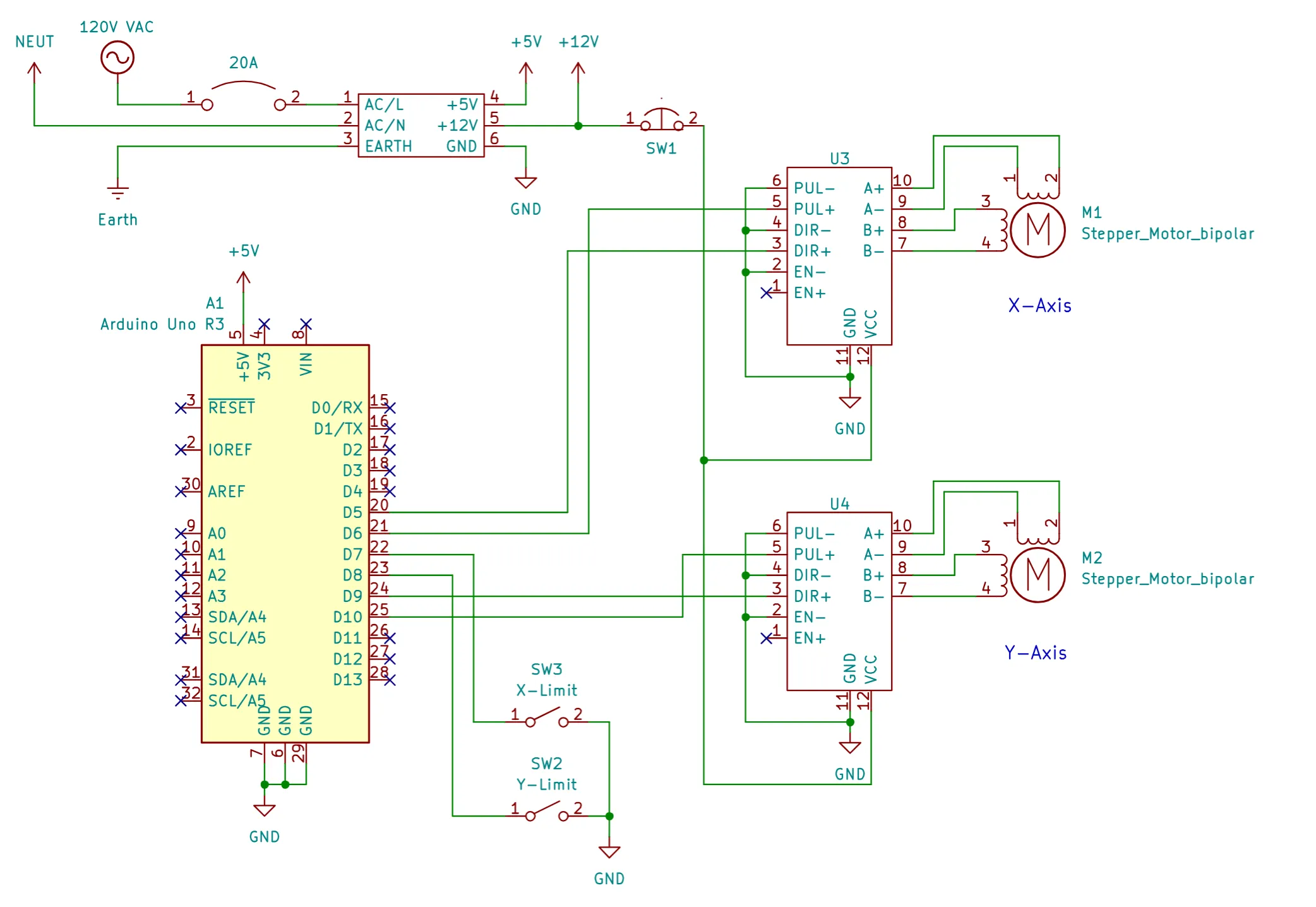

The whole system’s schematic looks like this:

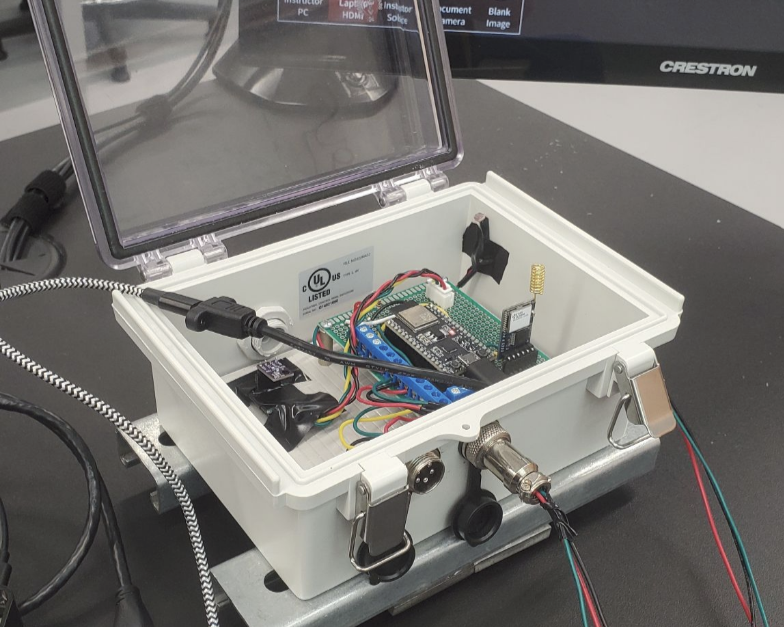

The electronics sport a 20A circuit breaker, an AC-DC power supply, an Arduino Uno R3 microcontroller, two limit switches used for homing, and a pair of stepper motors and drivers for the X and Y axes.

The stepper drivers’ 12V supply can be interrupted by an E-Stop switch in case the motors are doing something they shouldn’t be.

Software

The resistor sorter machine’s software suite primarily runs on a microcontroller. Specifically, the team has implemented an Arduino Uno board that controls the stepper motors and other electromechanical components needed to manipulate the resistors.

Manual input is currently needed to tell the gantry where to go, but eventually the coordinates will be determined automatically from the detected resistance.

The hardware control system is designed in such a way that it can receive commands over its serial interface from other systems. This results in a modular interface available to other projects, like a visual machine learning algorithm for identifying the resistors by their color.

Conclusion

The students on our project have the opportunity to mix with many different skill levels and learn something new every day.

Our project will continue for the next couple of semesters as we gradually implement the resistance detection system and other mechanical upgrades to make the sorter fully functional.